I have a Marmot Tungsten 1P tent that I’m pretty disappointed with, I’d only used it a couple of times before I noticed the seam sealing was flaking away from the inner floor and the fly. I’d tried re-sealing an old MSR Hubba Hubba with reasonable success making my own silicone/turps mix but I was keen to give tape a go so I bought a roll of ebay’s finest seam sealing tape from China. I’d never used it before so didn’t really know what to expect. Spoiler: This stuff is amazing!

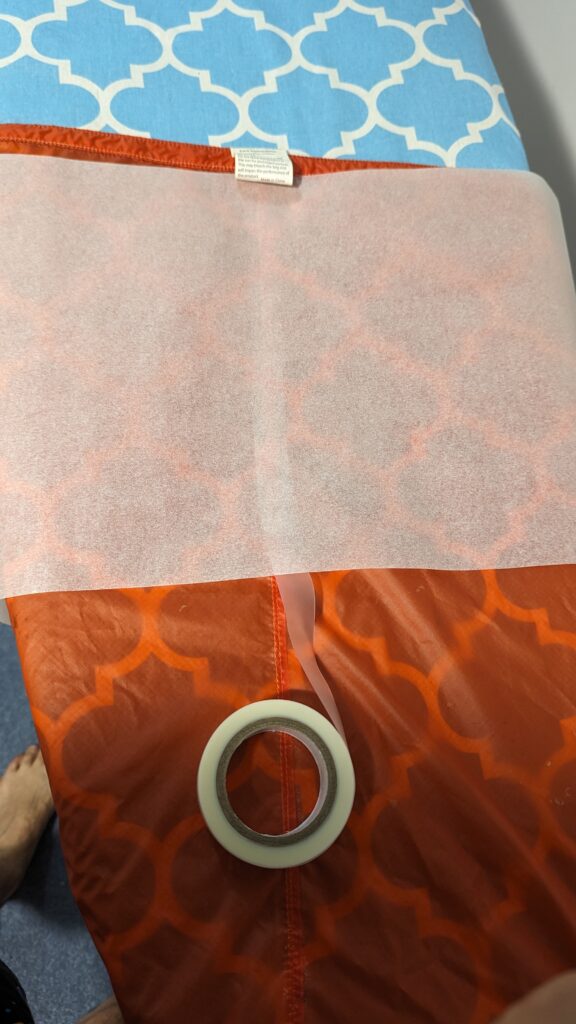

Rather than dive straight into doing the tent I figured I’d have a go at something easier so I dragged out a pack liner that I know had the same issue of seam tape peeling off.

First up I removed all the old tape which came away pretty easily. The plan was to use baking paper over the tape and a quick google said to set the iron to about 300F. Now I don’t even know what a Fahrenheit is and I’m pretty sure my $20 K-Mart iron wasn’t going to tell me so I set it on Wool/Silk and hoped for the best (Turns out that was a perfect temp).

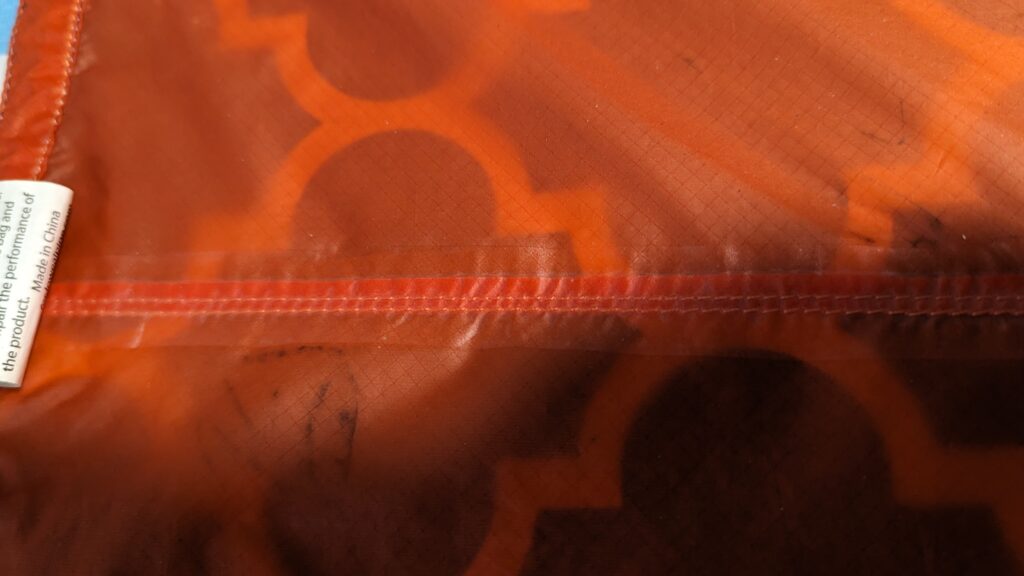

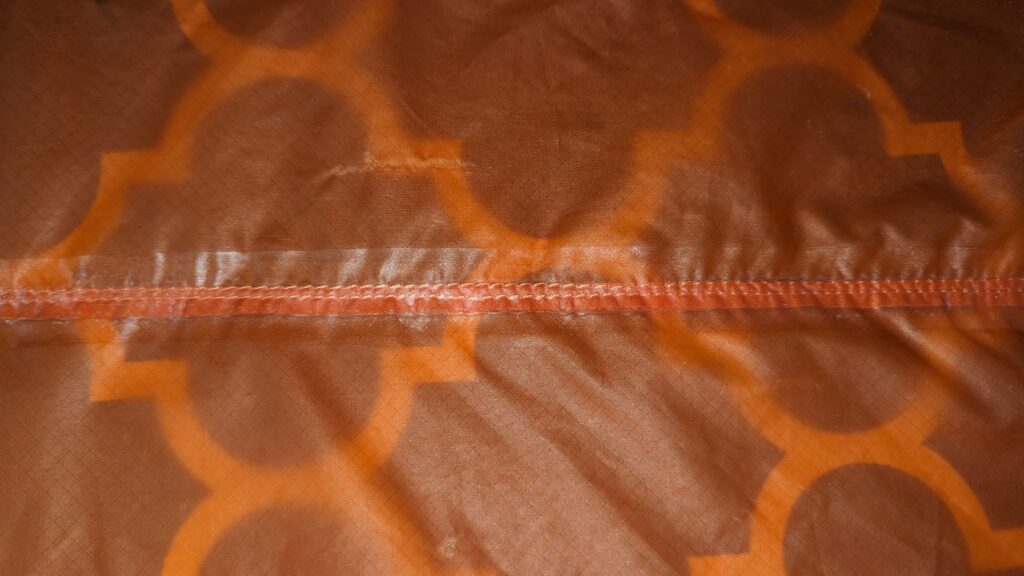

I lay the tape shiny side down over the seam and put the baking paper over it. Then, using the pointly tip of the iron i made my way along the seam, making little circles from the center of the seam out to the edges. You can kind of tell when it’s melted in because it kind of goes clear under the baking paper.

The first mistake I made was trying to go against the direction of the tape and I somehow melted the tape with the back of the iron, so don’t do that, just keep working in the one direction. The other thing I did was put a tea towel down to protect any areas I didn’t want to accidentally melt with the iron.

This setup worked really well but around the bottom was curved so I had to get creative and used a pair of rolled up socks to help keep the tape follow the seam. It actually worked really well.

After going over all the seams it’s worth just having a final check and making sure you’ve flattened out all the edges, it’s pretty easy to see any bubbles or sides that aren’t stuck down properly so just go over them again with the iron and a bit of baking paper.

After doing the seams I also went over a few pin holes and scratches I found. I tested it by dunking the whole liner in a basin full of water, no leaks! So yeah, seam tape, my new favourite thing!

Next up is to actually do the tent.